8 Tips for Buying a Table Saw

Before you buy a table saw, you should consider a few things in advance to avoid the wrong purchase. Below you will find eight buying tips and other optional features for professional use:

Sufficient power (watt)

The most important selection criteria should be the power of the motor (watts) and the idle speed. Only if both are sufficiently high, you will enjoy cutting to size (especially with harder materials such as hardwood). Otherwise, the speed can drop suddenly when cutting, and the sawing blade cannot create clean cuts. In the worst case, the saw blade wobbles, and the workpiece becomes unusable.

We recommend at least 1,000 watts (depending on the project) for normal models or good table saws under $500. Professional table saws usually have 2,000 watts or more.

The maximum possible cutting depth

The maximum cutting depth is also very important. This ultimately determines how strong/thick the material you want to cut with the table saw. We recommend 3 inches or more. If you decide on a table saw that is designed for a significantly smaller maximum cutting depth, the probability is high that you will often work at the device’s performance limit, which of course affects the service life of the saw.

A maximum cutting depth of 3 inches (or more) is recommended.

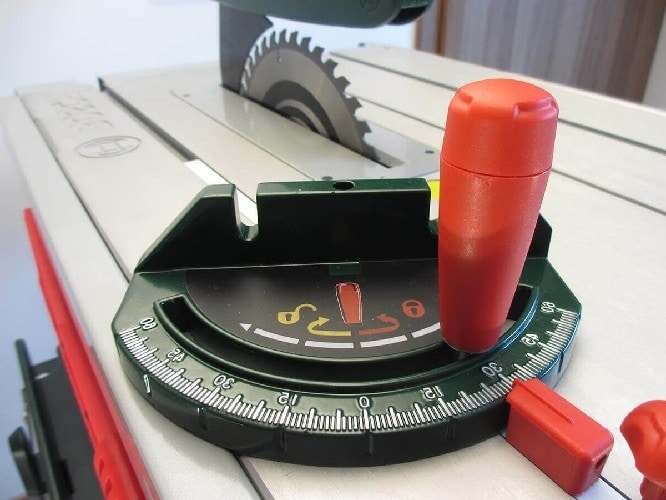

Cutting depth and cutting angle

Today almost all table saws offer the possibility of infinitely variable adjustment of both the cutting depth and the cutting angle. In this way, the saw blade can be optimally adapted to the strength/thickness of the workpiece to be processed. For miter cuts, the incline of the saw blade should be adjustable from 0 to 45 ° (in one direction; usually to the left). This enables flexible work. Professional table saws are also equipped with a so-called undercut function, which is particularly popular in furniture construction.

Both the cutting depth and the cutting angle (for miter cuts) should be infinitely adjustable.

Parallel and angle stop

A parallel fence and an angle fence should also be part of the scope of delivery. With the help of the rip fence, for example, several small strips of wood (slats) can be produced quickly and easily from a large wooden plate, without having to measure and mark each time again. The angle stop, however, allows various angle cuts. In the case of relatively cheap models, however, it should be said that the stops, due to their type of attachment, are often not 100% correctly adjustable and thus the quality and precision of the cut can suffer.

Parallel and angle stops should be included in the scope of delivery and work correctly.

Stable and spacious work table

The worktable of the circular saw is also one of the most important criteria. Good cutting results can only be achieved if this is sufficiently large and stable. So-called saw table extensions, which allow the cutting of larger workpieces, are recommended. The height adjustability of the worktable is also beneficial for the user, as this enables back-friendly and non-tiring work.

An important selection standard should be a large and stable (and possibly height-adjustable) work table.

Connection for dust extraction

If working dust-free is important to you, you should pay attention to the possibility of connecting an external extraction system (e.g. industrial vacuum cleaner). Today, however, this connection option is available on almost all models. A clear advantage here is always a clear view of the workpiece, as the sawdust is extracted immediately. If you have frequent use of the table saw, the use of dust extraction is also highly recommended in terms of health.

Dust-free work and a clear view of the workpiece is available thanks to the connection of an external extraction system such as an industrial vacuum cleaner.

Stable base

Not to be forgotten is the base of the table saw. This should be stable, and the saw should be stable and secure. In the ideal case, the base frame is also height-adjustable so that it can be optimally adapted to the size of the user. With very cheap hand-held circular saws, it is possible that the base frame is a bit “wobbly” and the saw vibrates slightly when cutting. An exact cut is then almost impossible. The base should be stable, so the saw should stand firmly and securely.

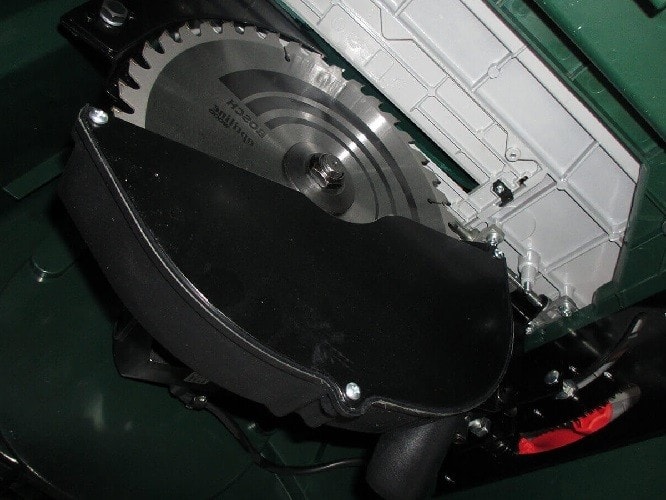

Safety

The topic of security should not be neglected when buying your own table saw. A protective hood over the saw blade and a riving knife is essential. Both prevent the rising saw blade from throwing small parts at the user. As a rule, a so-called push stick is also included, with the help of which the workpiece can be pushed over the saw table. It is also useful to protect the saw from overheating.

For your safety: Pay attention to a saw blade protection (protective hood), gap, push stick and overheating protection.

Optional professional features

The 8 points listed above should be part of the “basic equipment” of the table saw. If you want to do a little “more” with the table saw that goes beyond the “normal” DIY work, you should also pay attention to the following functions and features:

- Sliding carriage. A sliding carriage enables the workpiece to be guided very precisely (for example for angle cuts).

- Undercut function. If the table saw has an undercut function (the miter angle can be set from -1 ° to 46 °, for example), cuts can be made that allow, for example, two panels to be joined together.

- Pull function. With the help of the pull function, you pull the saw blade through the workpiece and not (as usual) the other way around. This makes the cut even more precise.

- Soft start. If the table saw has a soft start function, the motor does not start at full load straight away. This is good for the table saw and usually has a positive effect on its lifespan.

- Constant Electronic. Constant Electronic keeps the speed constant, no matter which workpiece (type, degree of hardness, thickness) is cut so that the saw blade is always clean and precise.